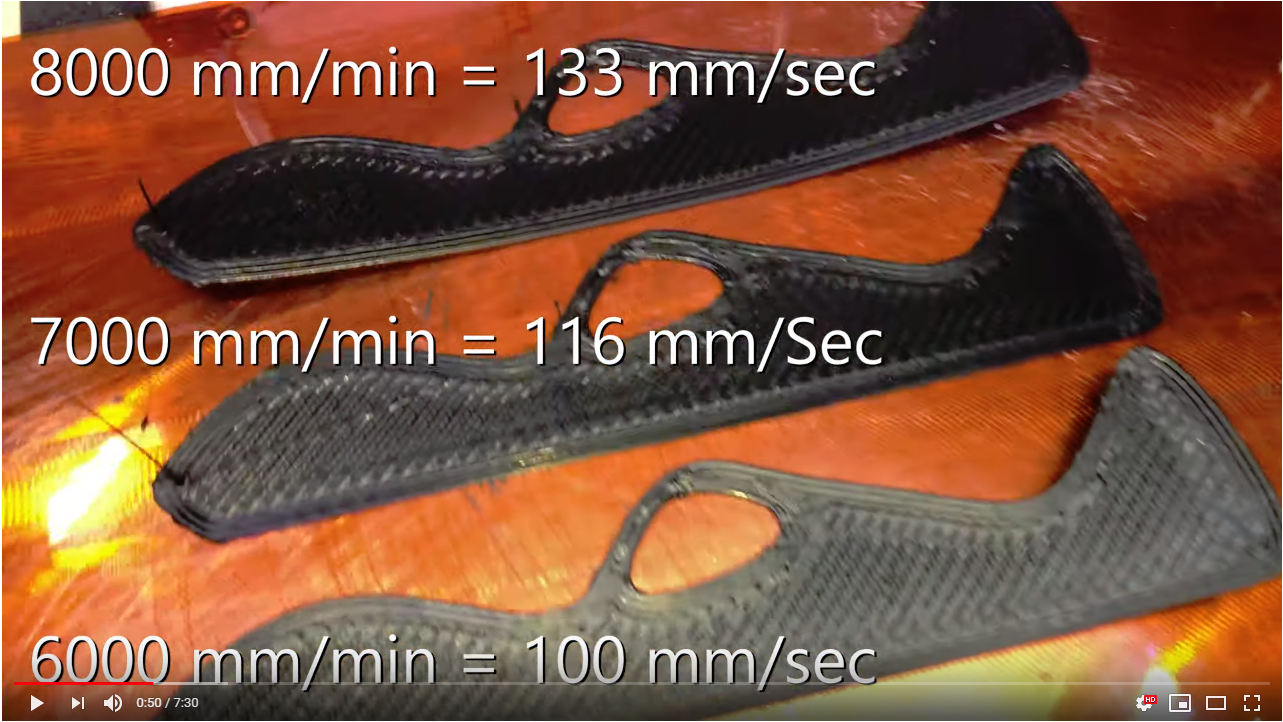

ETPU 95-250 Carbon Black filament printed at 8000 mm/min (133mm/s) with Bondtech extruder technology

Printing flex at these speeds in the video: 8000 mm/min = 133 mm/sec 7000 mm/min = 116 mm/Sec

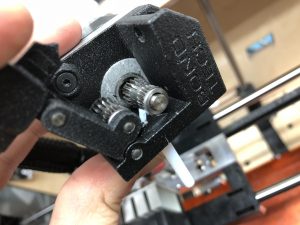

The tests where done on my upgraded Makerbot Replicator 1 (dual), it now has the outstanding Bondtech technology and PTFE tubing all the way down to the melt zone. The nozzle used is low friction 0,8 mm and the flexible, UV-stable and electrically conductive filament ETPU 95-250 Carbon Black is coated with a very thin layer of rapeseed oil to get lower friction in the tube. All shown prints have the same slicer settings (not optimal yet!), only the print speed was changed. It is clear that the filament feeding can handle more speed than the heater block and the over all movement stability of the printer. Also perhaps faster than the material extrusion rheologhy/melt flow index permits… 0,8 mm nozzle 0,33mm layers 220 deg C (set at 230, heater can´t handle the pressure)

MakerBot Replicator 1 (dual) upgraded with a Bondtech extruder and PTFE tubing close to the feeding, also a tiny bit of rapeseed oil on the filament to get low friction.

Check out a vase-mode test print here: https://youtu.be/eW8SMl2nL_Q

Comments are closed, but trackbacks and pingbacks are open.