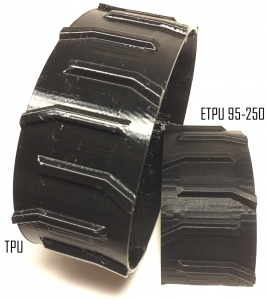

Professional Conductive , Flexible & UV-Stable 3D printing filament

Don´t need the conductivity?

Well the conductivity is great for some things but perhaps not your first choice? Then consider this:

This filament will give you some really nice benefits if the conductivity is not an disadvantage for your 3D printed design:

-

The material composition eliminates “stringing / webbing” issues.

-

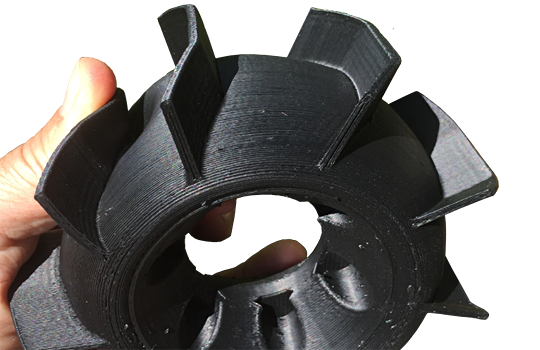

The hardness of 95 shore A and the carbon black filler makes for great print abilities.

-

The carbon black filler is an excellent UV stabilizer thus the prints are built to last in very harsh environments.

-

The matte black surface finish has a very exclusive look.

-

The material feels very nice and dry to touch.

-

It´s not too stretchy and will do great for timing belts etc.

“It prints really really well. In fact I like it more than ninjaflex in a lot of ways.”

– Andrew Troy Stott “Disrupt It Yourself” https://instagram.com/disruptityourself

“We’ve been using the conductive TPU filament, and it works great! We used the conductive TPU filament to prototype injection molded designs involving overmolded conductive silicone. It worked flawlessly, and was easy to use in our FlashForge Creator Pro.”

– Steve Trambert, Mechanical Engineer at http://pavlok.com

“We use the Palmiga Innovation conductive TPU filament to demo the ZYYX 3D Printers capabilities in printing flexible materials. In addition to the very useful conductivity property, it also gives excellent printing results!”

– Mats Moosberg, CEO, ZYYX 3D Printer http://www.zyyx3dprinter.com

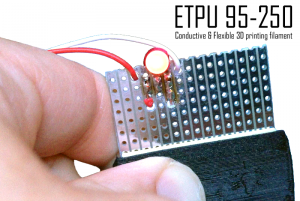

“PI-ETPU enables us to develop 3D printed soft sensors for biomedical applications. We are exploring the use of PI-ETPU for biopotential electrodes and force sensors.”

– Gerjan Wolterink, PhD candidate, University of Twente

“When it comes to flexible filaments, Palmiga ETPU is my first choice. The simplicity of printing, the strength of the print and the stylish matte surface make it my go to flex.”

– Emanuel Teljemo, Founder and developer at TE3D. www.te3d.se

PI-ETPU 95-250 Carbon Black the conductive and flexible 3D printing filament

|

Endurance

Easy

Exclusive

|

PI-ETPU 95-250 Carbon Black (Typical values shown, print method influences the values)

| Diameter ø | For 1,75mm printers: can maximum differ between 1.65mm to 1,9mm from spool to spool but within a singel spool the tolerance is approx ±0,05.

For 2,85mm printers: can maximum differ between 2.70mm to 2,95mm from spool to spool but within a singel spool the tolerance is approx ±0,05. |

mm | Measure before use for best results / Mät före användning för bäst resultat |

| Abrasion resistance / Slitstyrka | – | Excellent / Utmärkt | |

| Heat aging / Värmeåldring | Good resistance / Bra motstånd | ||

| Chemical Resistance / Kemisk motståndskraft | – | Excellent performance for greases, lubricants and some oils but is soluble in organic solvents and during hydrolysis. The most dissolving solvents are polar organic solvents, e.g. dimethyl formamide or dimethyl sulfoxide. Aliphatic alcohol and saturated/aromatic hydrocarbons such as petrochemicals may cause swelling of material and decrease of mechanical properties. / Utmärkt prestanda för tex fetter, smörjmedel och vissa oljor, dock upplöses den i organiska lösningsmedel och under hydrolys | |

| Microbial resistance / Mikrobiell resistens | Can be vulnerable to damage from fungi and bacteria when for instance used in contact with soil in either hot or humid environments / Kan vara känslig för skador från svampar och bakterier när den till exempel används i kontakt med jord i antingen varma eller fuktiga miljöer | ||

| Adhesion strength / Vidhäftningsförmåga | – | Good / Bra | |

| Low temperature flexibility / Lågtemperaturflexibilitet | – | Acceptable / Acceptabel | |

| Density / Densitet | 1,3 | g/cm³ | |

| Tensile Strength / Draghållfasthet | 15 | MPa | ISO 527, ASTM D-638, 10x4mm solid part |

| Yield Strength / Sträckgräns | 15 | MPa | ISO 527, ASTM D-638, 10x4mm solid part |

| Tensile modulus / Dragmodul | 12 | MPa | ISO 527, ASTM D-638, 10x4mm solid part |

| Elongation at Break / Brottöjning | 250 | % | ISO 527, ASTM D-638, 10x4mm solid part |

| Elongation at yield / Förlängning vid flytning | 225 | % | ISO 527 |

| Volume resistivity / Volymresistivitet | <800 | Ωcm | Calculated based on randomly measured 10cm filament, so far 30 to 750Ωcm between batches |

| Hardness / Hårdhet | 95 | Shore A | ISO 868 / D-2240, 10x4mm solid part (±4 Shore A) |

| Color / Färg | Black / Svart | ||

| Recomended Temperature range / Rekomenderat temperaturområde | 200-230 | °C | Depending on 3D printer and print speed / Beroende på 3D Printer och utskriftshastighet |

| Decomposition temperature / Sönderfallstemperatur | 250 | °C | |

| Self-ignition Temperature / Självantändningstemperatur | >340 | °C | |

| Pre-drying / Förtorkning | 90°C | 1 h | Only needed for optimal performance / Endast för optimalt resultat |

The filament is made from a special thermoplastic polyurethane (TPU) compound material with a carbon black filler witch is bound in the base polymer. The information in this data sheet represents typical values for the original standardized sample and should not be regarded as a fixed specification for all filaments. 3D-printing will affect these values. PI-ETPU 95-250 Carbon Black is a product under development and Palmiga Innovation reserve the right to change the properties at any time without notice. This product does not contain TNPP (Tris(nonylphenyl)phosphite).

This professional conductive and flexible 3D printing filament is made of a rubber-like TPU (Thermoplastic PolyUrethane) compound material with a carbon black filler witch is bound in the base polymer, it is the result of the inventor Thomas Palm´s (Palmiga Innovation, http://palmiga.com/) desire to 3D print some inventions of his.

Now you can enjoy this conductive and flexible 3D printing filament as well, go ahead and 3D print lots of inventions of your own!