What is TPU and ETPU 3D print material? Is it actually rubber?

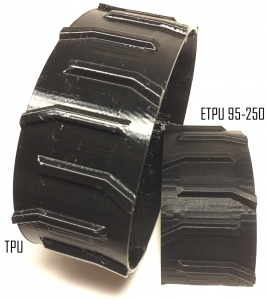

3D printing flexible TPU VS ETPU 95-250 filament

What is TPU and ETPU? TPU is short for Thermoplastic polyurethane and it´s an elastomer that is fully thermoplastic. ETPU is part of a brand name for the conductive TPU called PI-ETPU 95-250 Carbon Black, the “E” can be short for Engineered or Electrical…

TPU bridges the material gap between rubbers and plastics. Its range of physical properties enables TPU to be used as both a hard rubber and a soft engineering thermoplastic.

It has great physical properties for durable 3D prints, prints that can be used in final products that needs to cope with hard handling and not only for prototyping (like some simulation materials).

TPU offers flexibility without the use of sometimes problematic plasticizers (Migration of plasticizers out of their host plastics leads to loss of flexibility, embrittlement, and cracking. Also substantial concerns have been expressed over the safety of some plasticizers)

Thermoplastic polyurethane is any of a class of polyurethane plastics with many possible properties, they are thermoplastic elastomers consisting of linear segmented block copolymers composed of hard and soft segments. Molecular weight, ratio and chemical type of the hard and soft segments can be varied creating a huge versatility in material properties.

Whether for its outstanding toughness, durability or processing ease, TPU is a versatile performer that is great for many applications.

sandals, swimming fins, dampers/chock absorbers, tires, tank treads, bellows, constant velocity boots, V-belts, driving belts, timing belts, synchronous belts (or any other type to transfer power), couplings, grommets, pens for mobile phone or tablet displays, seals, flexible tubing, caster wheels, cattle tags, footwear, sport shoe soles, in-line skates, mining screens, abrasion protection, protective sports gear, sporting goods, googles etc…